The sealing material is used for preventing leackage of fluids in various equipment, devices, etc., and it is required to have a perfect function under difficult conditions such as high temperature, high pressure, high speed, and corrosive fluid.

It is necessary to select and use a suitable sealing material and quality to prevent loss of premature wear, stoppage, leackage, etc, and to perform normal functions.

Therefore, the sealing material is a small component, but its function and role are very important.

TYPES AND CHARACTERISTICS OF GASKET

Gaskets are classified into three types. Metal gaskets, semi-metallic gaskets, and non-metallic gaskets, depending on the constituent materials.

A. Metal Gasket

The metal is processed into a plastic shape, and is generally used at high temperatures and pressures up to 800°C and 400 kgf/cm2. There are Ring joint gasket and Metal equilibrium gasket.

B. Non-metal Gasket

It is composed of non-metallic materials such as rubber, resin, graphite, and asbestos, and is used in the low temperature and low pressure range or 300°C or less, about 30 kgf/cm2 or less.

Joint sheet, fluorine resin (P.T.F.E) gasket is typical, and recently expanded graphite gasket is also used.

C. Semi-metal Gasket

Semi-metallic gasket is a mixture of metal and non-metal materials. It is used in the range of medium temperature and medium pressure up to 500°C and 100kgf/cm2.

Spiral wound gasket and Metal jacketed gasket are typical.

Material selection

Selection of materials suitable for use conditions.

-Internal fluid temperature

-Test pressure and operating pressure

-Corrosive

-Flange shape

-Gasket width

SPIRAL WOUND GASKET

Spiral wound gasket is a kind of semi-metallic gasket. It is a very ideal gasket that has excellent sealing properties and is easy to replace. It is widely used for a wide range of sealing materials such as high temperature, high pressure equipment, cryogenic equipment, general piping flange, valve, boiler etc. of industrial, petrochemical, and shipbuilding industries.

□ Gasket Features

1) Centering Ring (Outer Ring)

- Centering function to install the gasket in the correct position

- Reinforcement of gasket body

- Easy to fasten and prevent over-fastening

2) Inner Ring

- When the pressure and temperature of the internal fluid are high

- In case of rapid corrosion and erosion by internal fluid

- When it is necessary to avoid the internal fluid remaining in the gap between the flanges

- When the gasket size is large (In the case of large diameter, the gasket structure becomes straight. As the elasticity becomes weak, it is desirable to use a mold with a constrained inner and outer diameter at 26B or higher.)

- Filler material is PTFE, Graphite

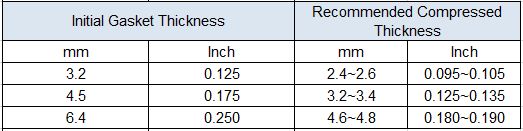

□ Recommended Compressed amount of spiral wound gasket

□ Thickness Range

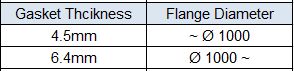

In the case of spiral wound gasket, the standard thickness is 4.5 mm. But, sometimes it is difficult to complete sealing due to eccentricity or bending of a large-diameter flange. So, the gasket thickness can be adjusted as below.

□ Metal strip (Hoop) material use temperature.

The maximum operating temperature of above data is the maximu operating temperature of the metal strip (hoop) of the spiral wound gasket.

When determining of the gasket, the filler material should be considered and applied.

□ Color coding of Spiral wound gasket by Material

- Material classification is based on inner ring

- Temporary blind gasket is all RED.

- Coloring is applied to 4 places in the 90° direction over 4", and coloring in 2 places to 180°below 4".

COMPRESSED ASBESTOS, NON-ASBESTOS JOINT SHEET

Compressed asbestos, non-asbestos joint sheet is uniformly heated and compressed into a plate which is mixed of asbestos or non-asbestos fibers, rubber and rubber vulcanizing agents, and other fillers.

□ Physical properties

- The heat-resistant temperature of asbestos or non-asbestos gaskets that make up the gasket is approximately 400 ° C for non-asbestos and 500 ° C for asbestos, but the heat resistance may vary by the manufacturer's manufacturing method. Over a maximum operating temperature, it is considered to be a factor that causes a rapid loss of stability, a decrease in physical properties due to a decrease in hardness, and at the same time, a loss of chemical resistance.

The maximum operating temperature and maximum operating pressure cannot be satisfied at the same time.

- Chemical resistance

The gasket's chemical resistance (various fluids) is classified according to the type of rubber binding material that the gasket is composed of, and generally rubber types are classified into NR, NBR, and SBR according to the use of the gasket.

- Compression restoration characteristics

It shows 7 ~ 17% compression at the compression load of 350 Kg / cm2 and the recovery rate is more than 40%.

Normally, it shows 12 ~ 15% compression amount at a load of 350 Kg / cm2 ~ 400 Kg / cm2, and stay in a state not restored until 200 Kg / cm2 when decompressed.

So, even the slight elongation of bolt has a significant effect on the gasket body pressure.

'Mechanical Study > Etc.' 카테고리의 다른 글

| Stainless Steel Material Properties (0) | 2020.03.21 |

|---|---|

| Hot Insulation / Cold Insulation Material (0) | 2020.03.18 |